Absorbers

An absorber is a device that partially or completely absorbs the incoming light or an EM wave for which it is designed. Absorption is one of the three phenomena that can happen to light as it hits the object. When light falls on an object, depending on the complex refractive index of the object, it can be transmitted, reflected, or absorbed. These parameters are related to each other by the following expression.

Where A is the absorptance (a measure of light absorbed in the material having a complex refractive index of n), Γ is the reflection (which is the measure of light bouncing off from an object in the direction of incident light), and T is the transmission from the material (which is the measure of light transmitted from an object in the direction of wave propagation).

Early accounts of perfect light absorbers

Salisbury screen light absorbers

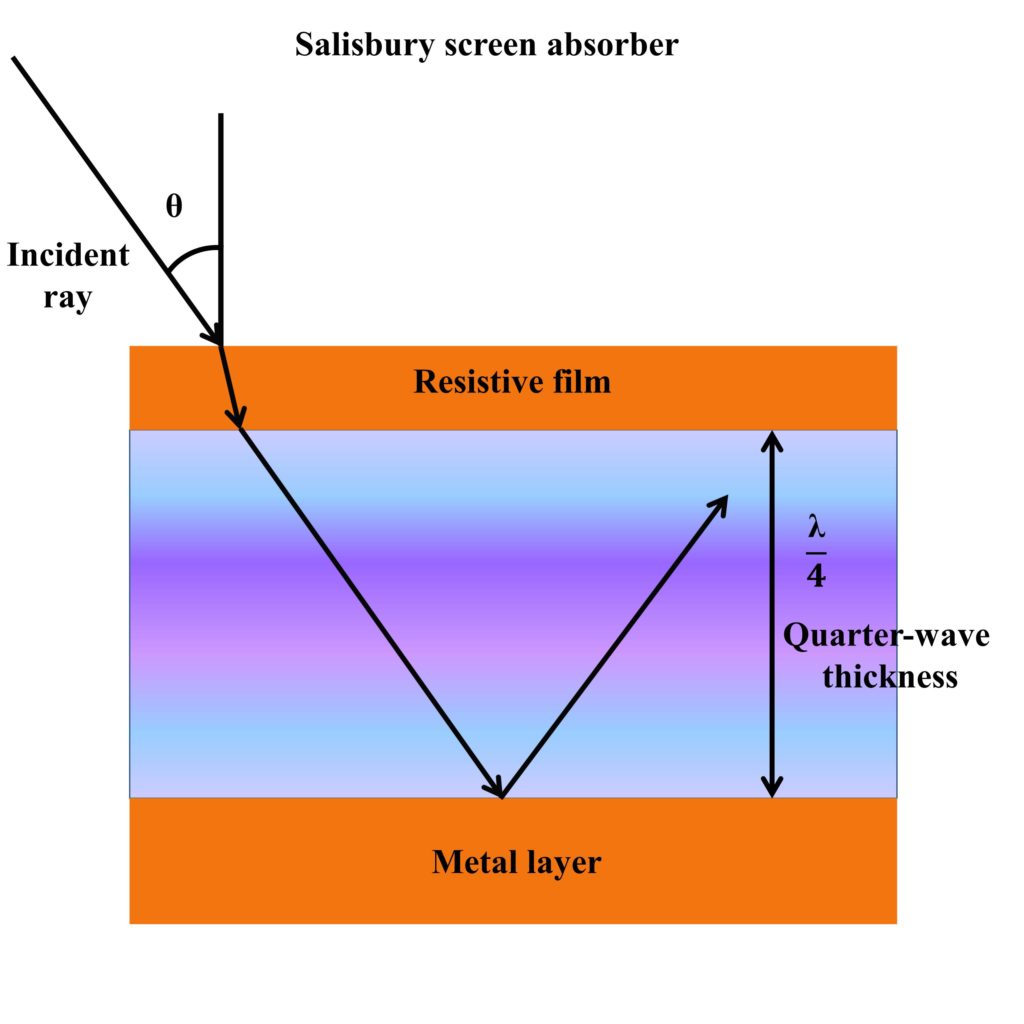

The idea of perfect light absorbers has been around for a long time, but the earliest evidence of specifically designed absorbers for a particular wavelength can be found in Salisbury screens, developed by Winfield Salisbury in the 1940s. The design of a Salisbury screen consists of a ground plane, dielectric layer, and a resistive sheet, therefore making the lateral geometry of a Salisbury screen metal-dielectric-metal (MDM). The ground plane is primarily made from metal, which is present at the bottom to eliminate transmission. The top resistive layer is usually also made from metal but a material with high extinction coefficient can also be used. The dielectric layer separates the top resistive film and bottom ground plane with a thickness of λ/4, where λ is the operational wavelength (a wavelength at which perfect absorption of light is required). The thickness of the dielectric layer is the primary reason for the absorption of the wave at operational wavelength because, at this thickness, the wave entering the dielectric medium travels a total distance of λ/2 before it leaves the resistive sheet after getting reflected from the ground plane. This makes the wave leaving out of the resistive sheet (after traversing through dielectric layer) to be out-of-phase from the wave that gets reflected from the resistive film (that does not goes through dielectric layer). These waves are then canceled, which achieves a perfect light absorption at operational wavelength. Since the thickness of the dielectric layer is designed for a single wavelength, the drawback of Salisbury is its narrowband absorption, which does not take the broadband nature of light into account. Therefore, it is a perfect light absorber at a particular wavelength.

Jaumann light Absorber

The obvious flaw or unsuitability of the Salisbury screen to be employed for absorption for a broadband regime was corrected by the Jaumann absorber, which overcomes the single-wavelength operation limitation of the Salisbury screen. The designs of the Salisbury screen and Jaumann absorber are almost similar where the Jaumann absorber also employs MDM layers. However, in the Jaumann absorber, the DM layers after the ground plane layer are repetitively stacked with varying dielectric layer thickness. Each of these dielectric layers is particularly tuned to absorb specific wavelengths and if the absorption peaks at different wavelengths are present closely in the electromagnetic spectrum, a broadband absorption effect can be realized. This stacking of layers increases the overall thickness of the Jaumann absorber, and therefore the cost of manufacturing such absorber.

The Salisbury screen absorber can be considered to be a metasurface absorber as the top resistive sheet layer is extremely thin. Moreover, the overall design thickness of such absorbers is also usually limited to be lower than the operational wavelength, making Salisbury screen absorber an important step towards the development of metamaterial and metasurface-based perfect light absorbers.